RichieNorthcott

Member

So I bought a snowflake projector light from eBay, something like this:

Overall the effect is good and it's surprisingly bright (total power consumption is IRO 7W)

I thought I'd have a go at make it DMX controllable, via an arduino or similar. The unit has three 'channels' - the motor rotation speed, and two different sized snowflakes with associated LEDs. Interestingly using the remote it's only possible to switch on both snowflake LEDs or neither - but I was thinking it might be possible to generated some interesting effects by having them controllable / dimmable individually.

There's some incredibly devious electronics I'm struggling to get my head around. The unit is 5V DC powered, but there's something clever going on with the LED driving. The motor speed would be an easy win, it just needs a PWM signal from a microprocessor which takes the value of a DMX channel

The LEDs have me stumped though. Connecting the LEDs direct to my 5V bench PSU they pull about 30mA, but via this circuit the consumption is more like 700mA per LED - they are mounted to a heatsink which gets quite warm. I'm thinking the whole board (which is multilayer) is some kind of boost converter, the PCB itself also gets warm (like it is the inductor in the circuit.)

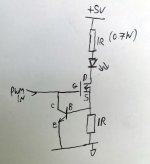

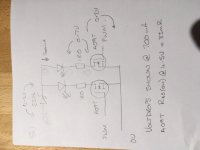

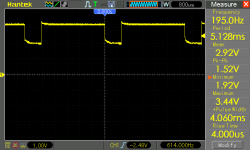

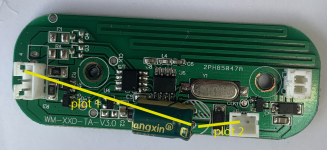

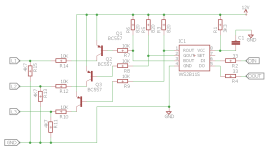

The unit is RF controlled i.e. there is a remote to turn on/off and adjust the motor speed. When powering up it defaults to 'on' so that might help me. There's an onboard 3.3V regulator for both ICs - I believe the IC on the left (unlabelled) is concerned with the RF side of things, it also has the crystal connected. The IC on the right controls the two LEDs - It has an input signal from the other IC, i've shown all 4 output lines in yellow but this unit is the 2 channel version. The yellow lines are a 3.3V 1KHz signal, 1ms low, then 4 ms high (so a duty cycle of 80%). The A09T SMD are p-channel MOSFETS (labelled Q2 and Q5), so my understanding is they are 'ON' for 20% of the time. The 3 pin connector goes to the LED board, top pin (shown in red) is at +5V, The lower 2 pins (shown in purple) are connected to the MOSFET drains via 1 ohm resistors (labelled 1R0). The MOSFET source pins appear to be direct to ground (when testing with a multimeter), but I'm thinking there some additional trickery in place.

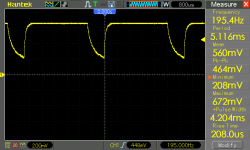

I tried removing the MOSFETS and driving via an external circuit (using N-channel with 20% duty cycle i.e. 4ms 'low', 1ms 'high' - but I don't get the crazy over-driven LED thing happening. I'm going to throw the word 'resonance' in as a suggestion?

I have no idea what's happening - I may end up making the motor speed controllable, but just a general on/off control from another channel (maybe 0-128 = off, 129-255 =on). Or perhaps single channel i.e 0 = off, 1-255 =LEDs on , motor slow to fast.

Any thoughts with what is going on with this clever circuit wold be greatly appreciated!

Overall the effect is good and it's surprisingly bright (total power consumption is IRO 7W)

I thought I'd have a go at make it DMX controllable, via an arduino or similar. The unit has three 'channels' - the motor rotation speed, and two different sized snowflakes with associated LEDs. Interestingly using the remote it's only possible to switch on both snowflake LEDs or neither - but I was thinking it might be possible to generated some interesting effects by having them controllable / dimmable individually.

There's some incredibly devious electronics I'm struggling to get my head around. The unit is 5V DC powered, but there's something clever going on with the LED driving. The motor speed would be an easy win, it just needs a PWM signal from a microprocessor which takes the value of a DMX channel

The LEDs have me stumped though. Connecting the LEDs direct to my 5V bench PSU they pull about 30mA, but via this circuit the consumption is more like 700mA per LED - they are mounted to a heatsink which gets quite warm. I'm thinking the whole board (which is multilayer) is some kind of boost converter, the PCB itself also gets warm (like it is the inductor in the circuit.)

The unit is RF controlled i.e. there is a remote to turn on/off and adjust the motor speed. When powering up it defaults to 'on' so that might help me. There's an onboard 3.3V regulator for both ICs - I believe the IC on the left (unlabelled) is concerned with the RF side of things, it also has the crystal connected. The IC on the right controls the two LEDs - It has an input signal from the other IC, i've shown all 4 output lines in yellow but this unit is the 2 channel version. The yellow lines are a 3.3V 1KHz signal, 1ms low, then 4 ms high (so a duty cycle of 80%). The A09T SMD are p-channel MOSFETS (labelled Q2 and Q5), so my understanding is they are 'ON' for 20% of the time. The 3 pin connector goes to the LED board, top pin (shown in red) is at +5V, The lower 2 pins (shown in purple) are connected to the MOSFET drains via 1 ohm resistors (labelled 1R0). The MOSFET source pins appear to be direct to ground (when testing with a multimeter), but I'm thinking there some additional trickery in place.

I tried removing the MOSFETS and driving via an external circuit (using N-channel with 20% duty cycle i.e. 4ms 'low', 1ms 'high' - but I don't get the crazy over-driven LED thing happening. I'm going to throw the word 'resonance' in as a suggestion?

I have no idea what's happening - I may end up making the motor speed controllable, but just a general on/off control from another channel (maybe 0-128 = off, 129-255 =on). Or perhaps single channel i.e 0 = off, 1-255 =LEDs on , motor slow to fast.

Any thoughts with what is going on with this clever circuit wold be greatly appreciated!

Last edited: