Renard 64XC Construction: Difference between revisions

| Line 62: | Line 62: | ||

|- | |- | ||

| | | | ||

* | * Install one (1) 6-pin IC socket for U6. This part is not included in the original Renard 64XC BOM. However, it is strongly suggested that you use sockets for this IC chip so it is included in the latest BOM. Insert the socket as per the silkscreen. Solder pin #1 and check the component for "slippage". Once the component placement is confirmed, solder the other 7 pins. This item does not require trimming. | ||

|| [[Image:Renard 64XC U6 Socket Install.jpg | 200px]] | |||

|- | |- | ||

| | | | ||

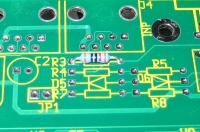

* | * Install two (2) 8-pin IC sockets for U4 & U5. These parts are not included in the original Renard 64XC BOM. However, it is strongly suggested that you use sockets for these IC chips so they are included in the latest BOM. Insert the sockets as per the silkscreen. Solder pin #1 and check the component for "slippage". Once the component placement is confirmed, solder the other 7 pins for each socket. These items do not require trimming. | ||

|| [[Image:Renard 64XC U4-U5 Socket Install.jpg | 200px]] | |||

|- | |- | ||

| | | | ||

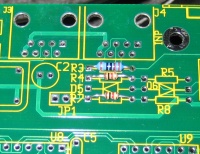

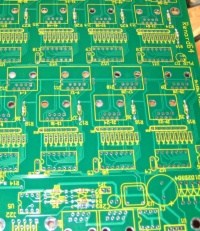

* Install eight (8) 14-pin IC sockets for U7-U14. Insert the sockets as per the silkscreen. Solder pin #1 and check the component for "slippage". Once the component placement is confirmed, solder the other 13 pins for each socket. These items do not require trimming. | * Install eight (8) 14-pin IC sockets for U7-U14. Insert the sockets as per the silkscreen. Solder pin #1 and check the component for "slippage". Once the component placement is confirmed, solder the other 13 pins for each socket. These items do not require trimming. | ||

|| [[Image:Renard 64XC U4-U14 Socket Install.jpg | 200px]] | |||

|- | |- | ||

|<center>'''INSTALLATION NOTE:''' </center> | |<center>'''INSTALLATION NOTE:''' </center> | ||

| Line 82: | Line 78: | ||

| | | | ||

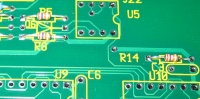

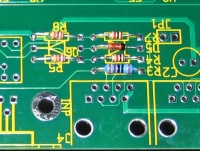

* Install the eight (8) 680 ohm resistor networks R10-R13 and R20-R23. The resistor network should have a dot on it to indicate pin 1. Insert pin 1 of the resistor network into the square solder pad. Sometimes a piece of tape is used to hold the resistor network in place while soldering the first pin. Once this is done, check the resistor network to ensure that it is straight and plumb to the board. If not, re-heat the first lead and reposition as required. Then, solder the other 7 pins. The leads do not have to be trimmed for this component. | * Install the eight (8) 680 ohm resistor networks R10-R13 and R20-R23. The resistor network should have a dot on it to indicate pin 1. Insert pin 1 of the resistor network into the square solder pad. Sometimes a piece of tape is used to hold the resistor network in place while soldering the first pin. Once this is done, check the resistor network to ensure that it is straight and plumb to the board. If not, re-heat the first lead and reposition as required. Then, solder the other 7 pins. The leads do not have to be trimmed for this component. | ||

|| [[Image:Renard 64XC R10-R13 R20-R23 Socket Install.jpg | 200px]] | |||

|- | |||

| | |||

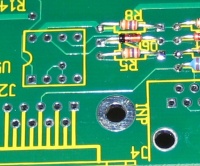

* Install eight (8) 0.1uF capacitors C3-C10. These capacitors are not polarized so the orientation is not critical. The resistor leads are already formed. However, sometimes they do not match the PCB holes exactly. Bend the leads as required to insert them into the PCB holes. Then, bend the leads back slightly to hold the capacitor in place. Solder and trim the leads the same as the resistors. | |||

|| [[Image:Renard 64XC C3-C10 Install.jpg | 200px]] | |||

|- | |- | ||

| | | | ||

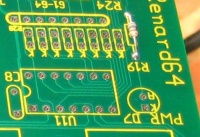

* Install | * Install sixty four (64) Green Channel LEDs. The LEDs are polarized and must be installed correctly. The long lead is the anode and must be placed in the square solder pad. The short lead is the cathode and this is marked on the silkscreen with a "K". Now, the question seems to come up a lot.."how do I get these straight?". Since the LEDs are rectangular, it is VERY noticeable if they are not. The best answer is to put them into the board and bend the leads back slightly as you would do for any other passive component. Then, put a piece of tape across the LEDs to hold them in place. Solder one lead on each LED and remove the tape. Now, you can reheat each single LED lead and make adjustments to line them up. Once you are satisfied, solder the other lead and trim the excess. The bottom edge of these rectangular LEDs is not smooth or uniform. So, if you want "perfect" alignment, be prepared to "lift" a few of the LEDs a bit to get them flush with their neighbors. | ||

|| [[Image:Renard 64XC Channel LED Install.jpg | 200px]] | |||

|- | |- | ||

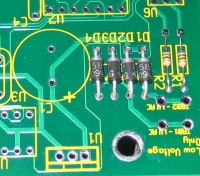

| | | | ||

* Install | * Install the Power LED, D7. The LEDs are polarized and must be installed with the proper orientation. The long lead is the anode and must be placed in the round solder pad that is marked with an "A". The flat side of the LED (the short lead side) goes in the square pad marked with a "K". This is exactly opposite of the Channel LEDs in the next step! Bend back the leads slightly as done with the resistors. Solder one lead and check from proper alignment. Then, solder the other lead and trim off the excess. | ||

|- | |- | ||

| | | | ||

Revision as of 23:05, 28 August 2010

Board Assembly

- Note: Pictures will be added as soon as they are available

- The following sequence of steps is by no means the only way to Assembly the Renard 64. It is simply a suggested order of assembly. Many builders have varied opinions on what the order should be. In general, you start with the "shortest" items and work towards the tallest. This generally means that resistors are first and connectors are last but every board is different.

- A good temperature controlled soldering iron should be used for building the Renard 64. Try to get the smallest diameter rosin core solder you can find (either 60/40 or 63/37). DO NOT USE LEAD FREE SOLDER!! This takes special equipment and a very high skill set that few DIYers have. If you do use Lead Free Solder and have problems (which is VERY likely) please let us know when you ask for help. Lead Free Solder can look like a good joint but still not be electrically conductive.

- One safety note is prudent here. Solder is METAL (lead and tin)...In order to use it,it must be MELTED. HOT, Molten Metal can BURN! Also, metal leads get hot while soldering. So, any unprotected fingers that are being used to "hold" a component in place will be burned!! Painter's tape is one way of holding items down while the board is being flipped over. Another way is to use another unpopulated board or flat surface to allow the board to be flipped while keeping the components in place.

- NOTE: The part numbers referenced in the following instructions are those taken from the Renard 64 BOM.

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |