blurp

New member

I've been having some trouble with putting the lights on my leaping arches, because when you get nearly done, you can't really hold it up in the middle, or prop it up, without tearing up the lights. So it sags very badly and makes it difficult to spin with the drill, because the person holding the drill has to hold the weight and try to keep it from sagging too bad.

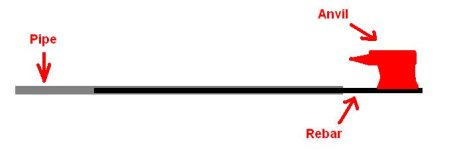

I found an easy way to support the pipe from the inside. I use a 10' piece of rebar with an avil sitting on one end on my work bench. Then I slid the pipe up on the rebar, and it supports the pipe very well and allows it to spin freely.

It's too cold out there to take a pictue right now, my camera keeps fogging up. So here's a cheap drawing to help explain it.

I found an easy way to support the pipe from the inside. I use a 10' piece of rebar with an avil sitting on one end on my work bench. Then I slid the pipe up on the rebar, and it supports the pipe very well and allows it to spin freely.

It's too cold out there to take a pictue right now, my camera keeps fogging up. So here's a cheap drawing to help explain it.