Soldering Basics: Difference between revisions

| Line 24: | Line 24: | ||

You do not have to clean most flux residue from a soldered joint, but it can help to clean them to see if there are bad joints. | You do not have to clean most flux residue from a soldered joint, but it can help to clean them to see if there are bad joints. | ||

Do not attempt to solder circuits that are connected to live power. | |||

|} | |} | ||

Revision as of 19:35, 7 April 2014

Intro

Soldering is easy! Many new members come to DIYC having never soldered a board before. Most people learn to solder and quickly are building their own controllers and spending the money they saved on more lights. There are numerous videos and tips listed below to help you learn to solder.

Soldering is joining two metal surfaces together using another metal that is melted and cooled to connect the two metal surfaces mechanically and electrically. In electronics you are joining the copper traces on the printed circuit board to the metal legs of the various electronic parts using special lead/tin solder.

The basic concept is to firmly attach the electronic part through the proper hole in the printed circuit board and then heat the joint up with a soldering iron. When both the copper trace and the component leg are properly heated, you then apply the solder wire to the joint and it will melt and flow around the copper and attach itself to the component leg. You then remove the soldering iron and the solder will cool and the liquid solder will freeze into a solid connection.

Disclaimers

The standard disclaimers pertaining to the information contained on this wiki page are listed here.

THIS WIKI PAGE IS NOT COMPLETE YET AND HAS NOT BEEN CHECKED FOR ERRORS.

Soldering quick tips

| The best solder joints come from a combination of good solder, good tools and practice.

A good solder like Kester 44 (use 63/37 with flux core and 0.032" diameter 1/2lb spool for starters) along with a good temperature controlled soldering like the CSI 1A, CSI 3DLF or the Tenma 21-10115 will result in good solder joints. It is common to set the iron temperature to 650 - 750 °F for a good joint. For under $10 you can buy a lot of spare parts and pcbs to practice on listed below You do not have to clean most flux residue from a soldered joint, but it can help to clean them to see if there are bad joints. Do not attempt to solder circuits that are connected to live power. |

Solder Types

There are many kinds of solder available, but it is important that you choose the correct solder to use on your electronics. You should only use lead/tin solder designed for circuit boards. Use of the wrong solder could damage your components and result in a board that does not operate correctly.

Electronic Solder

There are several types of electronic solder available. The most common types are:

- Lead/Tin solder

- "Silver" solder

- Lead-free solder

IT IS STRONGLY RECOMMENDED THAT YOU ONLY USE LEAD/TIN SOLDER FOR BEST RESULTS!!

Lead/Tin

The most common and proper solder to use is Lead/Tin. It is generally available locally from electronic part stores like Radio Shack or online from numerous vendors listed below.

- Lead/Tin solder is available in different mixtures of the two metals. There are two popular mixtures available:

- *63/37 (Called a eutectic mixture) It contains 63% Tin and 37% Lead and melts exactly at 183 °C (361 °F)

- *60/40 Is a common solder that contains 60% Tin and 40% Lead and melts over a range of 183–190 °C (361–374 °F)

- They both work fine for electronic work. It is a personal choice as to which you use. The main difference is how they both cool. The 60/40 when cooling goes through a "slushy" phase and does not always result in a bright shiny joint. The 63/37 eutectic solder cools quickly and does not go through the slushy phase. Many people prefer the 63/37 solder, but will use whatever is available when they have it!

- Care should be used when handling Lead based solders, you should always wash your hands when you are finished soldering and before eating. In practice there are very low levels of lead and decomposition products from the flux in the smoke from soldering, so it is a good idea to not inhale the smoke. You should also not put the solder in your mouth or chew on it....

"Silver" Solder

- Silver solder is similar to Lead/Tin solder, but has a small amount of silver (2-4%) added to it. It is more expensive and is not commonly used for printed circuit board work. It is a specialty solder sometimes used for parts that are already silver plated. The common silver solder eutectic mixture that is 62% Tin/36% Lead/2% Silver melts at 179 °C (354 °F). There is also a "Hard Silver Solder" that has 80%Silver in it and it is used for soldering jewelry and not electronics.

Lead Free Solder

- Lead free solder became popular in Europe on July 1, 2006 due to environmental laws associated with eliminating lead. It is generally not recommended for printed circuit board soldering by hobbyists. It is harder to get a good solder joint and is only used by manufacturers using special tools and processes.

Solder Forms

Solder comes in different shapes and forms depending on the type of soldering you are doing. The most common form is shaped like wire.

Solder Wire

Solder wire typically comes on spools. A 1 lb. spool will last a long time for hard core builder and 1/2lb spools are generally a good choice for most users.

Solder wire comes in different diameters. The most common ones are:

- 0.020” popular for fine work and hand soldering Surface mount devices

- 0.030” used for general soldering of through hole devices

- 0.040" used for soldering large connectors or very large components like fuse holders

The difference is a matter of personal choice, most people use 0.030" solder as a good overall compromise of speed and amount of solder they need for a joint. The larger solder often takes more heat and time to get a good joint. The smaller solder requires you to feed the solder in faster to get the proper amount of solder to make the joint. You are less likely to end up with excess solder on a joint with the smaller solder. For a good photo of the different sizes of solder compared to a integrated circuit chip, look here

Solder wire also comes with or without a flux core. Flux is a chemical that is in the middle of the solder that quickly melts and flows over the metal surfaces and cleans and wets the surfaces as you solder. It generally results in a better joint, but will often leave a harmless residue on the board.

Solder Paste

Solder paste is a gel that is a mixture of lead/tin solder and flux in a paste form. It is commonly used when attaching a surface mount device (SMD) to a printed circuit board. It is usually dispensed through a syringe with a needle tip. Solder paste has a relatively short shelf life of 4-8 months, and should be stored in a refrigerator when not being used. It is typically smeared across the fine copper traces and the part placed on top of it. When the paste is heated up using either hot air or a soldering iron, the paste melts and is drawn to the metal legs and traces.

Bad Solder

There are several types of solder that are commonly available, but should not be used for assembling printed circuit boards.

Pipe Solder (Commonly called Acid Core)

Pipe solder is commonly used to "sweat" copper pipes together for home water systems. It often has a different type of flux inside of it that is corrosive and can damage delicate electronic components. Even if you find non acid core pipe solder, it is often very large diameter (0.050 - 0.060") and is hard to melt and get a good joint. It is usually found in the plumbing department at home improvement stores. DO NOT USE PIPE SOLDER TO ASSEMBLE YOUR BOARDS!!

Lead Free Solder

Lead Free solder has its roots in Europe due to certain restrictive environmental regulations. It requires greater heat and is noticeably harder to get a good hand soldered joint compared to lead/tin solder. Lead Free solder is often sold right next to regular lead/tin solder in stores, so be careful when you buy your solder. BEGINNERS AND CASUAL USERS SHOULD AVOID LEAD FREE SOLDER. If it is the only solder available, it can be used with caution. For tips on using lead free solder read this article. For tips on repair and rework with lead free solde look here. It generally comes in two compounds Tin/Copper called SnCu or Tin/Silver/Copper (96.5% Tin, 3.0% Silver, 0.5% Copper) called SAC.

Stained Glass Solder

Solder used for stained glass manufacture is often available in large diameter wire (0.050 - 0.075") and in strips. It is generally used with a very large soldering iron specially designed to heat the large pieces together. It should not be used for electronic work.

Flux

Flux is a chemical available in either a liquid or gel form used to help make better older joint. Flux is commonly found in the center of solder wire, commonly called Rosin Core solder. Flux works by melting and flowing along the metal surfaces a

Soldering Irons

Temperature Controlled

Low Cost Uncontrolled

Soldering Guns

Soldering Tools

Soldering Iron Tips

How to select a soldering iron tip

Wire Cutters

Desoldering

Solder Suckers

Solder Braid

Tweezers

Holders

3rd Hand

Board Holders

Painters Tape

Magnifying Glass

Tip Cleaner

Soldering Iron Stand/ Holder

Electrostatic Discharge (ESD) Mat

Hand Tools

Fume Extractor

Flux Remover

Using Isopropyl Alcohol as a cleaner

http://www.chemtronics.com/c-263-flux-removers.aspx

http://www.mgchemicals.com/products/solder/flux-removers/

How to Solder

Preparation

Iron Temperature

Soldering technique

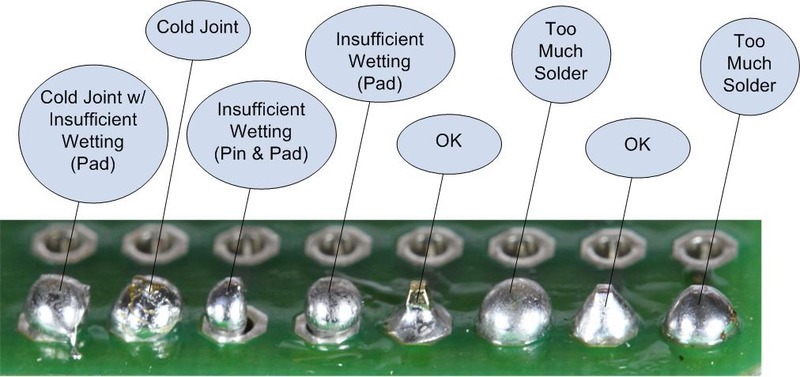

Common Soldering Problems

Good Guide to soldering problems

How to Desolder

Desolder Braid

http://www.chemtronics.com/descriptions/document/SIZINGGUIDE_LR.pdf

Solder Sucker

Desoldering Iron

Circuit Specialists 474A Desoldering station

How To Solder Videos

Soldering Renard Boards WayneJ's Video Instructions for soldering a Renard PCB

Curious Inventor's Soldering Basics Video tutorial that contains useful guidance on soldering, soldering tip hygiene and technique.

Curious Inventor's SMT Soldering Tutorial Video tutorial that contains guidance on SMT soldering techniques.

SparkFun SMT soldering tutorial PDF tutorial show techniques and methods for SMT soldering.

EEVblog #180 - Soldering Tutorial Part 1 - Tools

EEVblog #183 - Soldering Tutorial Part 2

EEVblog #186 - Soldering Tutorial Part 3 - Surface Mount

How To Solder Guides

Soldering is Easy: Comic book format beginners guide to soldering

SMT Soldering Comic book beginners guide to soldering Surface Mount Devices SMT

Solder and soldering articles

Vendors

Circuit Specialists Soldering irons, solder and tools

MCM Electronics Soldering irons, solder and tools

All Spec Soldering irons, solder and tools

Radio ShackSoldering irons, solder and tools

Hobby KingSoldering irons

Kester Solder Solder

Tayda sells low cost spare components and pcbs to practice on.

Soldering Practice

For less than $10 you can buy a large collection of parts and blank printed circuit boards from many vendors to practice on. One vendor, Tayda has a good selection of low cost parts and inexpensive shipping. They usually deliver in 5-10 days. An example of the parts you can buy for under $9 including shipping is:

| Description | SKU | Quantity |

|---|---|---|

| Small StripBoard 94x53mm (Copper) | A-5031 | 2 |

| Big StripBoard 110x93mm (Copper) | A-2384 | 1 |

| Prototyping Board 142x74mm | A-5052 | 1 |

| 8 pin DIP IC Socket Adaptor Solder Type | A-001 | 4 |

| 14 pin DIP IC Socket Adaptor Solder Type | A-004 | 4 |

| 6 pin DIP IC Socket Adaptor Solder Type | A-624 | 4 |

| 680 OHM 1/4W 5% Carbon Film Resistor | A-2075 | 20 |

| 1K OHM 1/4W 5% Carbon Film Resistor | A-624 | 20 |

| 0.1uF 50V Multilayer Monolithic Ceramic Capacitor | A-214 | 5 |

| LED 5mm Red Super Bright | A-1554 | 5 |

| BTA06-600C BTA06-600 Triac 600V 6A | BTA06-600C | 1 |

| 1N4004 Diode 1A 400V | A-156 | 4 |

| DG301 Screw Terminal Block 2 Positions 5mm | A-668 | 3 |

| IRLU024 MOSFET 65 mOhm 17A 55V N-channel I-PAK-3 IRLU024NPBF | A-1453 | 1 |

| LM7805 L7805 7805 Voltage Regulator IC 5V 1.5A | A-179 | 1 |

| 40 Pin 2.54mm Single Row Pin Header Strip | A-197 | 1 |

| 47uF 16V 105C Radial Electrolytic Capacitor 5x11mm | A-4522 | 5 |

This would give you 78 electronic components, 4 printed circuit boards and 285 solder joints you could practice on.....