10W-RGB-LED-DRIVER: Difference between revisions

Ukewarrior (talk | contribs) |

Ukewarrior (talk | contribs) |

||

| Line 59: | Line 59: | ||

</pre> | </pre> | ||

== Assembly == | == Assembly Tips == | ||

This board had only one part that will take some small amount of skill to install, the PT4115.<br> | |||

While this is an smd part, it can be hand soldered successfully.<br> | |||

The board can | To do so, you will need, some liquid flux.<br> | ||

This is the only part that really needs the liquid flux, however, you may also find it useful when you solder the LED.<br><br> | |||

The LED can be mounted to the top or the bottom of the board. <br> | |||

It may not seem like much, but this clearance difference can make a difference when retrofitting this board into a repurposed LED Flood Light assembly. | |||

Revision as of 01:31, 10 January 2015

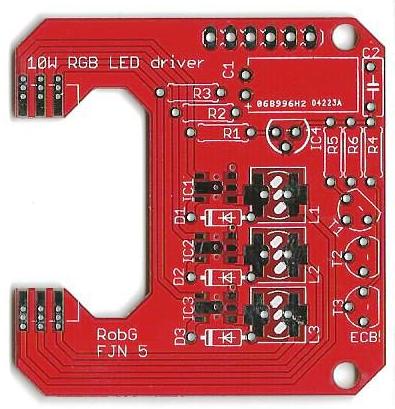

A Constant Current Driver Board for 10W RGB Modules

This circuit board is specifically designed to drive 10W RGB LED modules.

It has the ability to drive a 10W RGB LED via a 5v DC PWM signal that will therefore allow

dimming of each individual color.

As a separate 12V power source is applied to the board, three different connections are made to the board that can

control the brightness of each color separately.

These connections are typically the 5V DC output pins from a microcontroller.

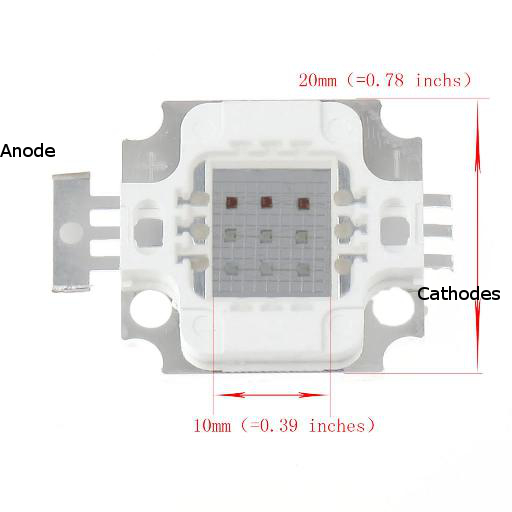

10W RGB LED

This board was specifically designed for a commonly found 10W RGB LED.

These square form factor LEDs can be found at many online stores, ebay and aliexpress.

Typically characteristics of these LEDs would be:

Color: RGB

DC Forward Voltage (VF): Red 6-8V, Green 9-12V, Blue 9-12V

DC Forward current (IF): 300MA

Output Lumens: Red 120-150LM, Green 200-300LM, Blue 70-100LM

Wave Length : Red 620-625nm , Green 515-520nm, Blue 455-460nm

Beam Angel: 140 degrees

Life span: >50,000 hours

As you can see from the picture to the right, these LEDs are not very large,

less than 1" square.

All three colors have a common Anode (+), and separate Cathodes (-) for each color.

Despite their size, do not be fooled into thinking these are like regular indicator LEDs that you see on circuit boards.

These units can generate enough heat to burn themselves out if not attached to a heatsink.

BOM - Bill of Materials

The BOM for this board uses both Surface mount(smd) and through-hole components.

The only mandatory smd part is the constant current driver IC, the PT4115.

The board can use either through-hole or smd inductors. The BOM shows through-hole inductors.

BOM for 12V DC power input:

QTY Board ID Description 3 IC1,IC2,IC3 PT4115 by Powtech: 30V, 1.2A Step-down High Brightness LED Driver with 5000:1 Dimming 3 L1,L2,L3 100uH Inductor, 6x8mm, 700ma 3 T1,T2,T3 Transistor FJN3314R 3 D1,D2,D3 Diode 1N5819 3 R1,R2,R3 Resistor, 1/4 Watt, 0.33 Ohm 3 R4,R5,R6 Resistor, 1/4 Watt, 4.7K (4K7) Ohm 1 IC4 Voltage Regulator, 5V 78L05 1 C1 Electrolytic Capacitor 100uF 35v (polarized) 1 C2 MLCC Ceramic Capacitor .1uF 50v (monolithic)

Assembly Tips

This board had only one part that will take some small amount of skill to install, the PT4115.

While this is an smd part, it can be hand soldered successfully.

To do so, you will need, some liquid flux.

This is the only part that really needs the liquid flux, however, you may also find it useful when you solder the LED.

The LED can be mounted to the top or the bottom of the board.

It may not seem like much, but this clearance difference can make a difference when retrofitting this board into a repurposed LED Flood Light assembly.