SSRez

Why Another SSR?

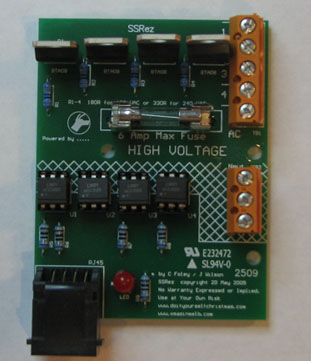

There are lots of SSR designs out there. However, Sean's SSRoz is one of the best. It is compact and functions great and without this initial work, the SSRez may not exist! However, a shortcoming of the design was that it was not designed with a specific enclosure in mind. The initial move towards the SSRez involved changing the layout to fit the TA-200 Telephone Demarc Enclosure from YourBroadbandStore.com.

In order to keep the board to a minimum size and the board cost down, the SSRoz has all the neutral connections off board. So, take all the neutrals and connect them with a large wire nut (five 16AWG neutrals!) Once connected, where does the massive chuck of wire go? :) This lead to adding terminals for the neutrals...now this is not inexpensive. The cost was offset in part by removing the vertical fuse holder and replacing it with inexpensive fuse clips.

Lastly, the RJ45 connector could be difficult to remove with the locking pin as the pin ends up in a tight corner. A vertical RJ45 jack made this so much easier.

While changing every thing around, the power traces were beefed up a bit to allow a slightly higher power throughput. This allows for a 7A fuse in place of the original SSRoz fuse of 5A.

so....start out trying to change one problem..and end up with a whole new layout!

Disclaimers

The standard disclaimers apply to the SSRez and can be found here.

Schematic

Coming Soon

Bill of Materials

QTY Mouser #: Description 1 571-5556416-1 Modular Jacks 8 PCB TOP ENTRY marked RJ45 1 504-GMC-7 5mm x 20mm Medium Time Delay Fuses 125VAC 7A Med Time Delay 4 511-BTA04-700T Triacs 4 Amp 700 Volt marked Q1, Q2, Q3, and Q4 2 534-3517 Fuse Clips and Holders PC FUSE CLIP 5 MM 1 604-WP7104IT LED Standard HI EFF RED TRANS marked LED 5 660-CF1/4C681J 1/4Watt Axial Leaded Carbon Film Resistors 680ohms 5% marked R5, R6, R7, R8 and R9 4 660-CF1/4C181J 1/4Watt Axial Leaded Carbon Film Resistors 180ohms 5% marked R1, R2, R3 and R4 4 859-MOC3023 Optocomponents Optocoupler TRIAC marked U1, U2, U3 and U4 4 571-1-390261-1 IC Sockets 6P ECONOMY TIN (Optional!) also marked U1, U2, U3 and U4 5 538-39890-0302 Eurostyle Terminal Blocks 5.0MM ECONOMY 2P 14-24AWG

Now the above is the base Bill of Materials for 120VAC operation. There are, however, some options that can be handled. These are listed below.

240VAC Operation

Change R1, R2, R3 and R4 to 330 Ohm and replace the fuse with one rated for 240VAC (one listed is for 125VAC). However, a fuse with a rating of 7A at 250VAC is a heck of alot of power. It is perfectly okay to use a fuse with a lower rating if your overall load is small.

36VAC Operations

Change R1, R2, R3 and R4 to 47 Ohm. The fuse rating is still a MAX of 7A. It does not change because the voltage has been reduced.

24VAC Operations

Change R1, R2, R3 and R4 to 33 Ohm. The fuse rating is still a MAX of 7A. It does not change because the voltage has been reduced.

FireGod

If the SSRez is going to be used with a FireGod system, Resistors R5-R8 may need to be changed. If the channel LEDs are used on the field modules AND the interface board voltage regulator is 5VDC, replace R5, R6, R7 and R8 with 510 Ohm Resistors. You must also use the "Sinking Code" with the SSRez.

Construction Information

This is a work in Progress!!! Pictures will be added as they become available.

Oh, many of you will be building more than one SSRez at a time. An assembly line mindset really helps. This means, put all the resistors on all the boards before going to the next part.

Now, get your tools together! Cause here we we go.....

- Sort your parts in the order of assembly. This sounds odd but really helps especially if you have never done this type of assembly before.

- Check your resistors...make sure the part matches whats written on the bag. Every once in a while, the supplier will give you the wrong part. It never hurts to grab a mulitmeter and check those resistors values.

- Inspect your boards for damage. Basically, you are looking for cut traces, deep scratches and other damages since they were shipped.

- Install the 5 680 Ohm Resistors marked R5, R6, R7, R8 and R9. Bend them first to match the holes (I have been known to bend all my resistors while watching TV!) Insert them through the holes and bend the lead back to about 60 deg on both side to hold them in place. Solder each connection and trim off the excess lead with flush cut snips. Note: Some electronics folks will tell you to do this differently. There is a high specification soldering procedure (typically for military items) that says to cut the leads to length, and then solder them in place. This will work but this level of detail is not required for this board.

- Install the 4 180 Ohm Resistors for 120VAC operation or the 330 ohm resistors for 240VAC operation. These are marked R1, R2, R3 and R4. The installation process is the same as in Step #4.

- Install the optional 6 pin sockets for U1, U2, U3 and U4. Beware of the orientation of the notch. This is a visual aid to make sure that you put the MOCs in correctly. Match the notch with the notch in the silkscreen. Sometimes, a piece of tape can help here. I usually put all four on, cover them with a board and just flip it over. Solder the six pins on each socket. If you choose not to install the sockets, then install the 4 MOCs here in the same manner.

- Install the Power LED. Orientation is critical. The short leg (the Cathode or K) of the LED must go into the square pad. The silkscreen has this marked with a K Bend the legs out to a 60 deg angle to hold the LED in place. Then solder the leads and trim the excess.

- Now its time for the RJ45 Jack. The jack should snap into the 2 large mounting holes and hold itself in place. The pins are very small and solder very fast so be careful not to add too much solder.

- The 5 terminal blocks are next. The terminals must be assembled first. There is a notch and a pin on the side to mate the 5 parts into on long 10 position terminal. Once assembled, insert the block into the board with the openings for the wires facing outboard. Starting from the middle and working outward, solder in all the pins. These pins are a bit larger and can take more heat and solder than the previous items.

- The fuse clips are next. Be aware the orientation of these as well. There is a small ridge inside the clip to keep the fuse from sliding out axially. This ridge must go to the side opposite the fuse. Using a fuse to hold the two clips in place while soldering has been suggested.

- Last, but not least, the TRIACs. These pins are large and they can be difficult to solder at first. If you have problems...tin the leads prior to inserting them into the boards. Solder the pins in place and trim the excess.

- Clean the board with Isopropyl Alchohol to remove any residual flux.

Wiring

Diagrams Coming Soon

Heat Sink

Template Coming Soon