Hello all,

I purchased an addressible momentary switch for my "push for music" setup (https://www.amazon.com/dp/B0988V21SM) and I have a 12V power system. My goal was to put a buck converter near the pole, and use that to step down to 5V for the switch, since it's the only 5V pixel I have in my display. (https://www.amazon.com/dp/B08JZ5FVLC)

I got all the parts, and wired it up, but it didn't work in my test setup.

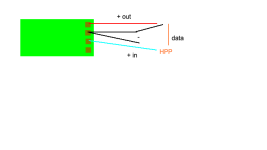

Hinkx Pix Controller (12V) -> Buck converter > Switch is what I did. (attached)

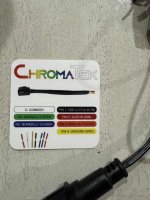

However, I'm getting 12V in the output regardless. I tried "cutting" and soldering the 5V diagram on the back, but either i dont understand what I'm doing, or I have faulty cuips. Regardless, I'm replacing the Bucks with something better and clearer to me. (https://www.amazon.com/Adjustable-Converter-Step-Down-Regulator-Stabilizer/dp/B081N6WWJS)

My question is, am I going about this correctly, or am I missing something more fundamental?

TIA

I purchased an addressible momentary switch for my "push for music" setup (https://www.amazon.com/dp/B0988V21SM) and I have a 12V power system. My goal was to put a buck converter near the pole, and use that to step down to 5V for the switch, since it's the only 5V pixel I have in my display. (https://www.amazon.com/dp/B08JZ5FVLC)

I got all the parts, and wired it up, but it didn't work in my test setup.

Hinkx Pix Controller (12V) -> Buck converter > Switch is what I did. (attached)

However, I'm getting 12V in the output regardless. I tried "cutting" and soldering the 5V diagram on the back, but either i dont understand what I'm doing, or I have faulty cuips. Regardless, I'm replacing the Bucks with something better and clearer to me. (https://www.amazon.com/Adjustable-Converter-Step-Down-Regulator-Stabilizer/dp/B081N6WWJS)

My question is, am I going about this correctly, or am I missing something more fundamental?

TIA