Power Injection: Difference between revisions

mNo edit summary |

|||

| Line 107: | Line 107: | ||

|style="background:#FBEC5D; color:black"| [http://www.mouser.com/ProductDetail/Eagle-Plastic-Devices/441-R360D-GR/?qs=GP7tGcbp1QS0bASKeHq6DA== 441-R360D-GR] | |style="background:#FBEC5D; color:black"| [http://www.mouser.com/ProductDetail/Eagle-Plastic-Devices/441-R360D-GR/?qs=GP7tGcbp1QS0bASKeHq6DA== 441-R360D-GR] | ||

|} | |} | ||

===Fuse blocks=== | |||

[[File:FB-10 lrg.jpg|200px]]<br> | |||

There are also fuseblocks sold that allow for fusing your power injection wires at one common location. Here are examples of [http://www.powerwerx.com/fuses-circuit-protection/10-circuit-blade-fuse-block-cover.html 10 Fuse] [http://www.powerwerx.com/fuses-circuit-protection/6-circuit-blade-fuse-block-cover.html 6 fuse] fuse blocks. | |||

===Fuses=== | ===Fuses=== | ||

Revision as of 23:03, 6 January 2016

Intro

When working with low voltage (5VDC and 12VDC) LEDs and Pixels it is common to have to add power injection to the end of long strings of lights to overcome voltage drop caused by the high current used by the LEDs over the small wire that is commonly used. A classic symptom of the voltage being too low at the end of a pixel string is the pixels may look Pink instead of White when turned on fully White. If the color of the first pixel in a string is different from the last pixel in the string, it is likely due to the voltage drop in the string and the wires supplying it. Other symptoms of too high of a voltage drop in a system are: random flickering, Pixels not responding to signals, and poor color lighting.

Using a formula called Ohm's Law you can calculate the effect of the voltage drop by entering in the wire size and the power drawn by the LEDs or Pixels. It is important to choose the correct Wire Size for your layout to minimize voltage drop. There are online tools like the Voltage Drop Calculator that can assist you in calculating the impact of the wire size vs. power needed. This Thread discussed how to use the Voltage Drop Calculator.

When voltage drops in the system are in the 5-10% range some issues may develop in the Pixels with their color. When the voltage drop exceeds 10-20%, then the Pixels may not respond properly or the color matching can be very poor. It is generally a good idea to test out your layout with the correct size and lengths of wires before installing the Pixels to confirm that the level of voltage drop gives an acceptable performance.

Disclaimers

The standard disclaimers pertaining to the information contained on this wiki page are listed here.

THIS WIKI PAGE IS NOT COMPLETE YET AND HAS NOT BEEN CHECKED FOR ERRORS.

General Concepts

- Always use the proper size fuses and fuse holders to protect your system from damage. Choose a fuse rating based on your Pixel current requirements.

- Install Fuses between Power Supplies and Controllers

- Install Fuses between Controllers and Pixels or LEDs (If output fuses are not installed on the Controllers)

- Install Fuses between Power Supplies and Power Injection Wiring.

- Install Fuses anyplace you reduce the wire size to a smaller wire for power distribution.

- Use the largest diameter wire that you can to minimize voltage drop to circuits. The lower AWG wire gauge numbers are larger diameter wire. #18AWG is thicker than #20AWG.

- DO NOT TIE TOGETHER POSITIVE (V+) OUTPUTS FROM DIFFERENT POWER SUPPLIES!!

- ALWAYS TIE TOGETHER NEGATIVE (V-) OUTPUTS FROM DIFFERENT POWER SUPPLIES AND PIXEL CONTROL SIGNAL FEEDS.

- Only connect one power supply to each LED or Pixel string.

- Using the correct Wire Size will often allow you to use up to 50 5VDC Pixels and 100 12VDC Pixels without Power Injection.

- Choose Power Supplies that have have a high enough current rating for your system.

- Instead of using a larger wire size, it is possible to run 2 or 3 pairs of wire in parallel to decrease the power drop on longer runs.

- Remember that the voltage drop occurs in both the Positive (V+) and Negative (V-) wires, so you need to increase the size of both wires.

- On dumb RGB with a common Positive (V+) wire, the voltage drop is 3x the drop of the individual RGB wires due to the entire current using the same wire. You must use a larger size wire for the common Positive (V+) wire.

- Using Power Injection at the end of a String nominally reduces the current thru the wire to the beginning of the string in half, since the Power Injection Wires carry roughly half of the current for the string.

- Using Power Injection allows you to use smaller wire (higher AWG) to provide power to the pixels due to the reduced current thru each of the two pairs of wires connected to the Pixel string.

- Using Power Injection allows you to use your Pixels further from the Pixel Controller due to the reduced current thru each of the two pairs of wires connected to the Pixel strings.

- 12V Pixels are less likely than 5V Pixels to need power injection.

- Pixels with 18 AWG wire between the Pixel Nodes are less likely to need Power Injection then those with 20 AWG wire between the Pixel Nodes.

Pixel System Power Components

- Power Supplies

Power Supplies often have an adjustment on them that allow you to slightly raise the output voltage to compensate for minor voltage losses in the wiring. DO NOT adjust the power supply more then +0.3VDC higher then the nominal setting or you risk damaging the electronics on the Pixel Controllers and the Pixels themselves. Power Supplies often come with multiple output terminals connected in parallel to a common buss. - Power Supply to Pixel Controller Power Wiring and Fuses

The output wires from the Power supply that connect to the Pixel Controller carries the highest current of any wire in a Pixel system. It is critical to use the appropriate wire size and Fuse on this section of wiring. It is common to use 12-14 AWG wire for short distances between the Power Supply and the Pixel Controller mounted in the same enclosure. The CG-1500 provides a large enclosure that you can mount both a power supply and a controller inside of. A heavy gauge Fuse Holder with the proper size fuse should be used when connecting the positive output (V+) between the power supply and the Pixel Controller. Choose a fuse based on the expected maximum current usage of your pixels. - Pixel Controller

Many Pixel Controllers like the E682 use multiple power feeds to help cut down the size of the wire needed to feed the power to the board from the power supply. The E682 has two power supply feeds with a common negative (V-) connection between them. Each power feed terminal powers 1/2 of the output terminals. It is possible to drive two different voltage pixels from the two power feeds. The E682 has 5A individual output fuses connected to each output terminal. Generally you should not try to drive more then 50 pixels without using Power Injection due to the current draw being too high for the on board 5A Mini Fuse. - Pixel Controller to Pixel Power Feed Wiring and Fuses

The wire that runs from your Pixel Controller to your Pixel strings can often cause the biggest issues with voltage drop. It is important to keep these wires as short as possible and as large as possible. The various pixel vendors sell wire that is 18-20AWG and this can drop the voltage quickly over longer distances. When using long lengths of wire( >20ft), it is often necessary to use larger gauge wire (10-16 AWG)to limit the voltage drop. - Pixel Connectors

Waterproof modular Pixel Connectors are commonly used to allow easy setup and tear down of display items. The Pixel connectors come with at least two wire sizes, some have 20 AWG and others have 18 AWG wire in the pigtails and cables. The smaller wire (20 AWG) causes a higher voltage drop, but may be fine for short lengths. The TEE connectors can provide a simple modular way to provide power injection and pass control signals between two strings. - Pixel String Wiring

Pixels commonly come with 18 or 20 AWG wire between the Pixel nodes. The 18 AWG wire is preferred since it results in a lower voltage drop, but the thicker wire is more costly from the vendors. Most vendors will make Pixels available with 18 AWG wire upon request if it is listed as having thinner wire. - Power Supply to End of Pixel String Power Injection Wiring and Fuses

Because all of the components listed above all lead to some form of voltage drop, it is often necessary to add power injection to the end of the pixel string. By adding the wire from the power supply (or Pixel Controller) to the end of the Pixel string, you dramatically reduce the voltage drop near the end of the Pixel string. You also effectively cut the current drawn thru the wiring from the Pixel controller to the beginning of the string in half because the other half of the current is supplied by the power injection wire. Because these wires are directly connected to the power supply, it is critical that a fuse of the proper size be added inline as close to the power supply as possible. Choose a fuse based on the expected maximum current usage of your pixels.

Wire

When choosing wire for power feed and power injection, the wire size and length are critical. Common wire used for Pixels include larger gauge (10-18 AWG) Speaker wire, Security Alarm Wire, Low voltage landscaping wire, Sprinkler wire, SPT wire and various wire types available from the pixel vendors. You must pay attention to the wire size (thicker is better) and length (shorter is better) to ensure that the voltage drop over the wire is not excessive. For more information about how to calculate the proper wire size needed, look here. Do not use thin wire (20-26 AWG) like Cat5 or Cat6 wire. The voltage drop over thin wire is often too high to allow the pixels to operate properly. Thin wire also is a safety hazard and can heat if too high a current is used on it.

Wire Sizing in Pixel Systems has more information about how to chose the right gauge wire.

Using Fuses and Fuseholders

DC Power Supplies are capable of putting out hundreds of watts of power and causing serious damage, always use properly sized fuse for safety!

Due to the very high current that many power supplies are capable of putting out (>60A) it is a good design concept to use a heavy gauge wire inline fuse holder between the power supply and the controller hookup. The large gauge wire will minimize any voltage drop that may occur in the wire due to high current. The fuse is a safety factor to prevent the full power from the power supply from discharging thru a short circuit and potentially causing a fire. The correct size fuse rating should be selected based on the expected power usage of the units hooked up to the power supply. It is common to use large gauge > 10-14 AWG wire to connect power supplies with high count pixel controllers like the E682.

- Fuses should be installed in several places:

- Install AC line fuses between your wall outlet and your Power Supplies

- Install Fuses between Power Supplies and Controllers

- Install Fuses between Controllers and Pixels or LEDs (If output fuses are not installed on the Controllers)

- Install Fuses between Power Supplies and Power Injection Wiring.

- Install Fuses anywhere you join a larger wire to a smaller wire for power distribution.

Fuseholders

Mouser.com carries several inline weather resistant DC fuseholders that take automotive blade style fuses both ATC and Mini style fuses. You can also find similar fuseholders at Radio Shack, your local auto parts store, Lowes, Ebay, or DX.com.

| Fuseholders | ||||||

| Current Rating Up to |

Wire Size | Fuse Type | Mouser Part # | |||

|---|---|---|---|---|---|---|

| 30A | 12AWG | ATC | 441-R347A-GR | |||

| 30A | 12AWG | ATC | 576-FHAC0002ZXJ | |||

| 20A | 14AWG | ATC | 441-R347B-GR | |||

| 10A | 18AWG | ATC | 441-R359D-GR | |||

| 30A | 12AWG | Mini | 441-R360A-gr | |||

| 20A | 14AWG | Mini | 441-R360B-GR | |||

| 10A | 18AWG | Mini | 441-R360D-GR | |||

Fuse blocks

There are also fuseblocks sold that allow for fusing your power injection wires at one common location. Here are examples of 10 Fuse 6 fuse fuse blocks.

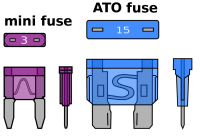

Fuses

Fuses come in two general types:

- AC Fuses to protect equipment plunged in wall outlets (110VAC)

- DC Automotive style fuses to protect wiring and components connected to the DC power supplies.

Automotive style blade fuses come in two types:

- ATC and ATO fuses are available with ratings of 1, 2, 3, 4, 5, 7.5, 10, 15, 20, 25, 30, 35 and 40A.

- Mini fuses are available with ratings of 2, 3, 4, 5, 7.5, 10, 15, 20, 25, 30A.

Fuse Color Coding

Blade fuses use a common coloring scheme for the Mini and ATC/ATO styles.

| Color | Current Rating (Amps) |

|---|---|

| Black | 1 A |

| Gray | 2 A |

| Violet | 3 A |

| Pink | 4 A |

| Tan | 5 A |

| Brown | 7.5 A |

| Red | 10 A |

| Blue | 15 A |

| Yellow | 20 A |

| Clear | 25 A |

| Green | 30 A |

| Blue-green | 35 A |

| Orange | 40 A |

Choosing a Fuse Size

Choose the fuse and fuseholder based on the maximum current that you expect from your Pixels to draw thru the smallest section of wiring. Choosing the correct fuse size can be a complicated matter with many options. For more detailed information about fuse size or selection look here , here , here and here.

Many Pixel Controllers like the E682, E6804 and the Renard PX1 have separate output fuses connected to each output connector already on the controller. A common rating for those fuses are 5A. They are generally Mini fuses.

You MUST use a fuse between high current power supplies and your pixel controller to protect the wiring between the power supply and the pixel controller input.

General Fuse Rules:

*FUSES ARE NOT OPTIONAL, THEY MUST BE USED TO PROTECT PEOPLE AND PROPERTY FROM DANGEROUS CONDITIONS!

*According to Littlefuse: "Always follow NEC guidelines for applying low-voltage fuses. Generally, the MINIMUM fuse size should be based on 125% of the circuits full load current. Time-delay fuses should be used for inductive loads and fast-acting fuses used to protect non-inductive loads."

*The maximum fuse rating should not exceed 1/2 of the maximum current capability of the smallest wire protected by the fuse.

*Fuses should be placed as close to the power source as possible.

*Fuse ratings need to be adjusted for temperature and number of conductors in a wiring bundle.

*Never install a fuse with a larger amp rating than specified for the fuse holder.

* According to the NEC the maximum fuse size for the following wire sizes are:

** 18 AWG Copper Wire 7A

** 16 AWG Copper Wire 10A

** 14 AWG Copper Wire 15A

** 12 AWG Copper Wire 20A

** 10 AWG Copper Wire 30A

CHECK WITH AN ELECTRICIAN TO CONFIRM THE APPROPRIATE FUSE RATINGS AND WIRE SIZES!

Fuses work by melting the internal element based on the current flowing through the fuse. The time it takes for a fuse to open is dependent upon the amount of current that flows through the fuse and it's rating. The more you exceed the fuse rating by drawing higher current through the fuse, the faster it will blow.

| Fuse Characteristics ATO Fuse Littelfuse | ||||||

| % of Fuse Rating | Current Rating | Minimum Opening Time |

Maximum Opening Time | |||

|---|---|---|---|---|---|---|

| 100% | 35-40A | 100 Hours | - | |||

| 110% | 1-30A | 100 Hours | - | |||

| 135% | 1-2A 3-40A |

0.5 Seconds 0.75 Seconds |

10 Minutes 10 Minutes | |||

| 200% | 1-2A 3-40A |

0.1 Seconds 0.15 Seconds |

5 Seconds 5 Seconds | |||

| 350% | 1-2A 3-40A |

0.02 Seconds 0.08 Seconds |

0.5 Seconds 0.5 Seconds | |||

| 600% | 1-30A 35-40A |

- - |

0.1 Seconds 0.15 Seconds | |||

Example: A 5A fuse that has 6.75A (135% of rating) flowing through it, will open in sometime between 0.75 Seconds and 10 Minutes.

Choosing the Proper Wire Size For Pixel Projects

Click here for information about choosing the correct wire for pixel and power injection wiring.

Single Power Supply Without Power Injection

This is a common layout for:

- Shorter Megatrees

- Arches

- PX1 Controller with 50 Pixels connected directly to it

When short (<50 Pixel) Pixel strings (with heavier gauge 18AWG wire between the pixels) are directly connected to a Pixel Controller, or they only have a short length (<10ft) of larger gauge wire (10-18 AWG) connected between the Pixel Controller and the Pixel Strings, you generally do not have to add power injection to the ends of the pixel strings. The system layout would look similar to this:

Single Power Supply Power Injection

It is common to use a larger common power supply for all pixels connected to Pixel Controller like the E682. The central power supply is often located in the same enclosure as the Pixel Controller. This is a common layout for:

- Tall Megatrees

- Shorter Megatrees with Folded Pixel Strings

- Layouts where the central controller is a distance from the Pixels

- Pixels the have thinner wire (20awg) between them

- Layouts that use thinner wire (18-20awg) from the controller to the Pixels

- Long lines of Pixels

- PX1 Controller with more than 50 Pixels connected directly to it

<50 Pixel String

When short (<50 Pixel) Pixel strings (with 18-20AWG wire between the pixels) that have a longer length (>10ft) of medium gauge wire (18-20 AWG) connected between the Pixel Controller and the Pixel Strings, you generally have to add power injection to the ends of the pixel strings. The system layout would look similar to this:

>50 Pixel String

When longer (>50 Pixel) Pixel strings (with 18-20AWG wire between the pixels) that have a longer length (>10ft) of medium gauge wire (18-120 AWG) connected between the Pixel Controller and the Pixel Strings, you generally have to add power injection after every 50 Pixels in the string. If you mix wire sizes anywhere along the way, you must add an additional fuse at that point as well to protect the smaller wire. The maximum fuse rating should not exceed 1/2 of the maximum current capability of the smallest wire protected by that fuse. The system layout would look similar to this:

When you very long strings (>100Pixels) you should inject power after every 50 Pixels in the string. The system layout would look similar to this:

Multiple Power Supply Injection

In some layouts with Pixels located a long distance (>30ft) from the Pixel Controller and the Central Power Supply it is often helpful to use a second Power Supply located closer to the pixels. This eliminates the need for long large gauge wires running long distances to places like roof tops or fence lines.

DO NOT CONNECT THE POSITIVE (V+) WIRES BETWEEN MULTIPLE POWER SUPPLIES!!!

YOU MUST CONNECT THE NEGATIVE (V-) FROM MULTIPLE POWER SUPPLIES AND THE PIXEL CONTROLLER.

<50 Pixel String

When short (<50 Pixel) Pixel strings (with 18-20AWG wire between the pixels) that have a longer length (>30ft) of medium gauge wire (18-120 AWG) connected between the Pixel Controller and the Pixel Strings, In some layouts it may be easier to use a second power supply located closer to the pixels and not use the central power supply connected to the Pixel Controller. The system layout would look similar to this:

>50 Pixel String

When longer (>50 Pixel) Pixel strings (with 18-20AWG wire between the pixels) that have a longer length (>10ft) of medium gauge wire (18-120 AWG) connected between the Pixel Controller and the Pixel Strings, you generally have to add power injection after every 50 Pixels in the string. In some layouts it may be easier to use a second power supply located closer to the pixels and not use the central power supply connected to the Pixel Controller. The system layout would look similar to this:

When longer (>50 Pixel) Pixel strings (with 18-20AWG wire between the pixels) that have a longer length (>10ft) of medium gauge wire (18-120 AWG) connected between the Pixel Controller and the Pixel Strings, you generally have to add power injection after every 50 Pixels in the string. In some layouts it may be easier to use a second power supply located closer to the pixels to supply power only to the pixels after the first 50 pixels which are powered by the central power supply connected to the Pixel Controller. The system layout would look similar to this:

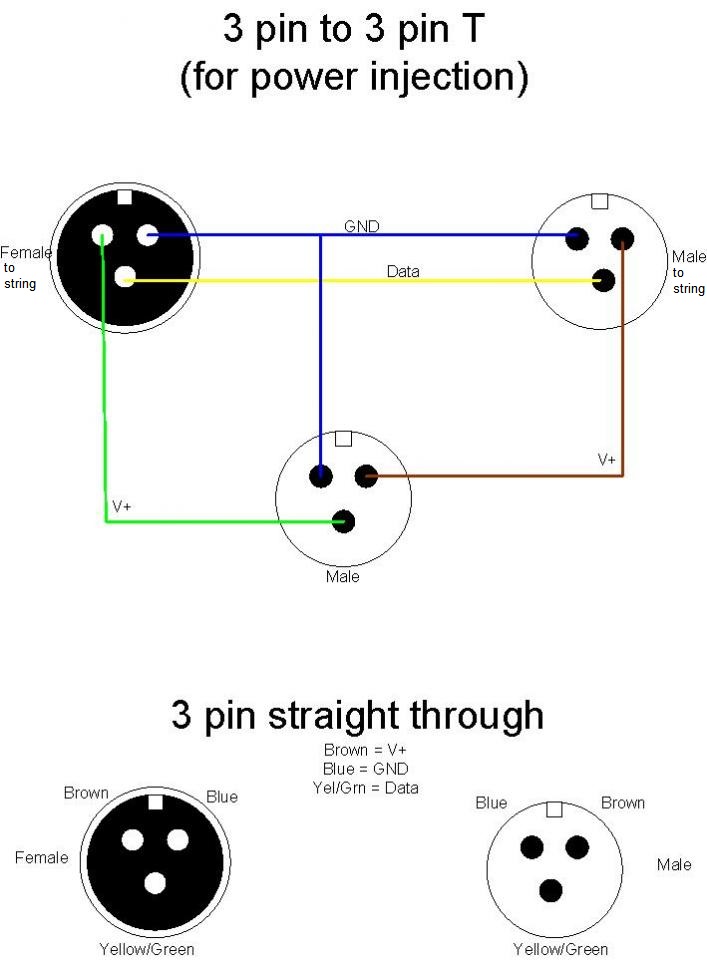

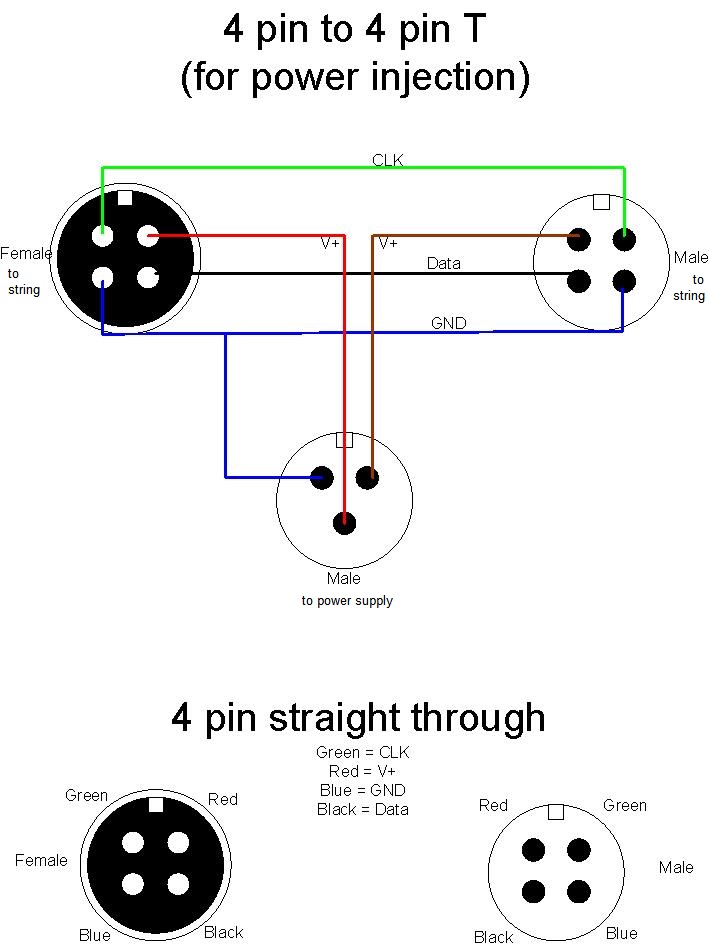

Power Injection using an TEE

The diagrams below shows power injection using a waterproof TEE connector. The one described is from DIYLEDEXPRESS. No matter which supplier you use, ALWAYS verify the pin out/color coding due to manufacturing differences/errors to ensure you are connecting your strands correctly.

Related Links

Different Styles of Pixels

Controllers

Dumb RGB or Intelligent Pixels??

Things You Will Need To Get Started With Pixels

Pixel Wiring Colors

Pixel Connectors

Choosing a Pixel Voltage: 5V vs 12V

Power Supplies

Waterproofing Pixels

Null Pixels

E1.31 Network Setup and Configuration