james70818

Master Rigger

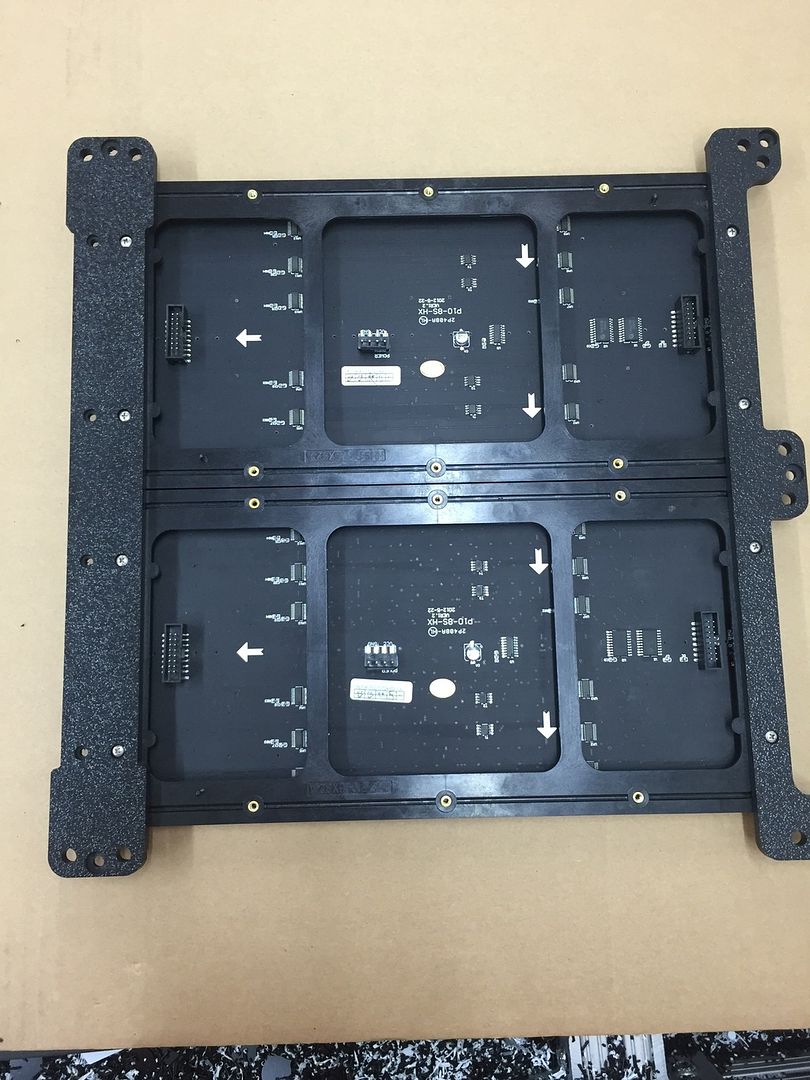

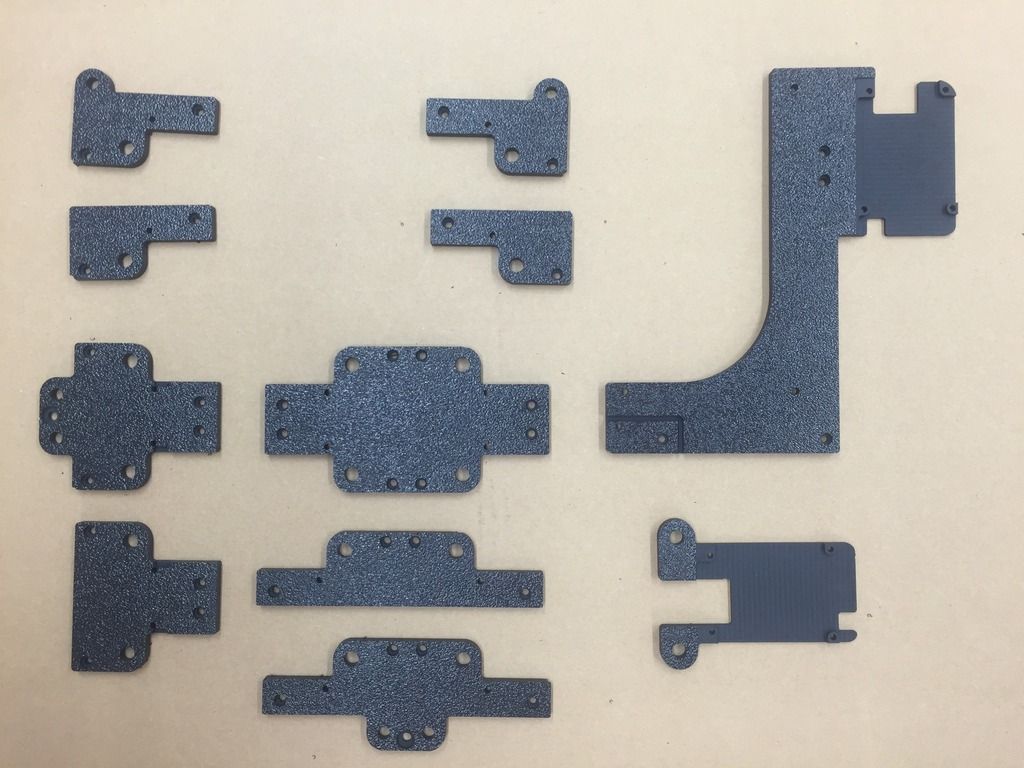

I think I'm done with the final tweaks. I played a little with the tolerances to help fit a little more variation between P10 Manufacturers.

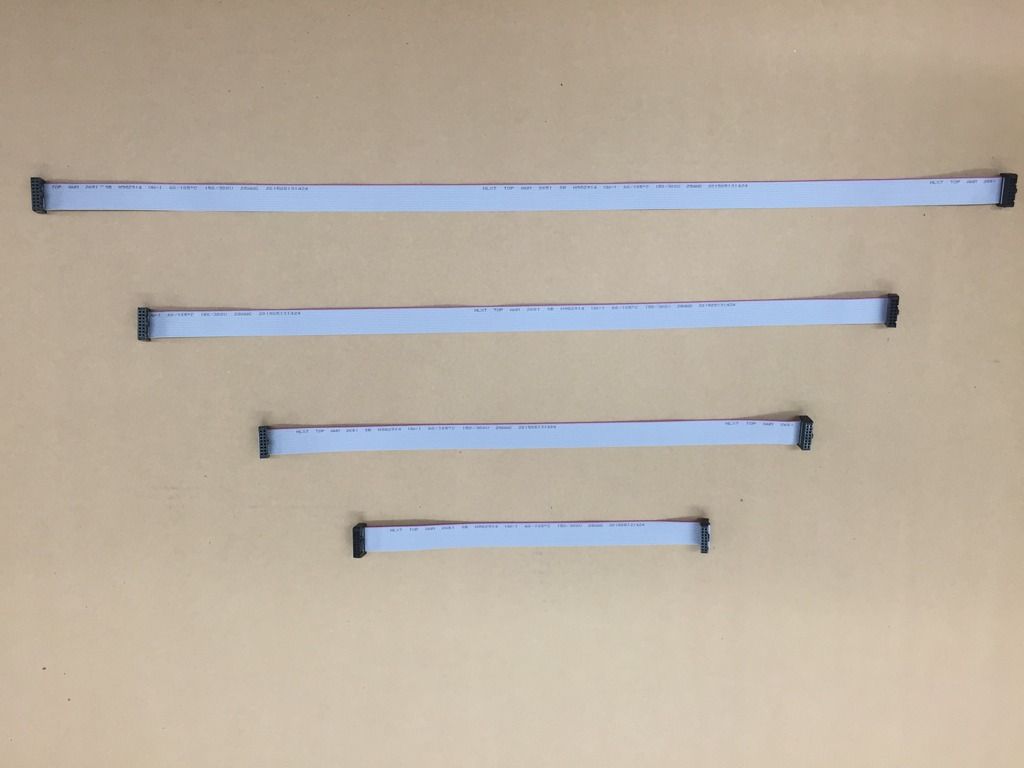

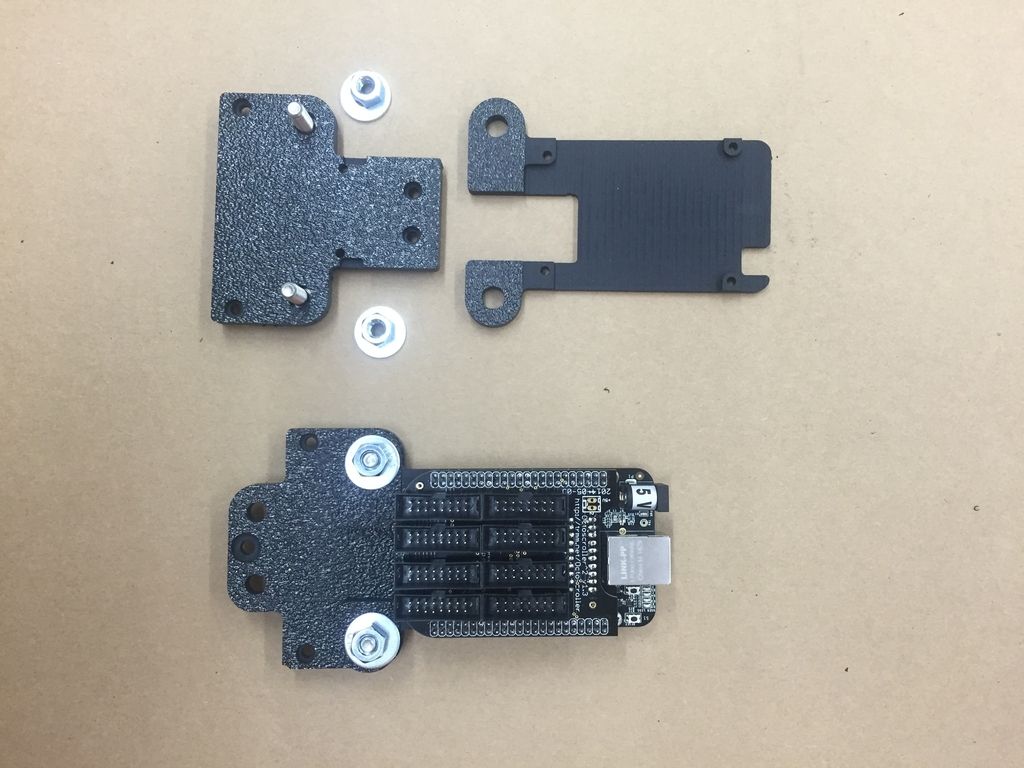

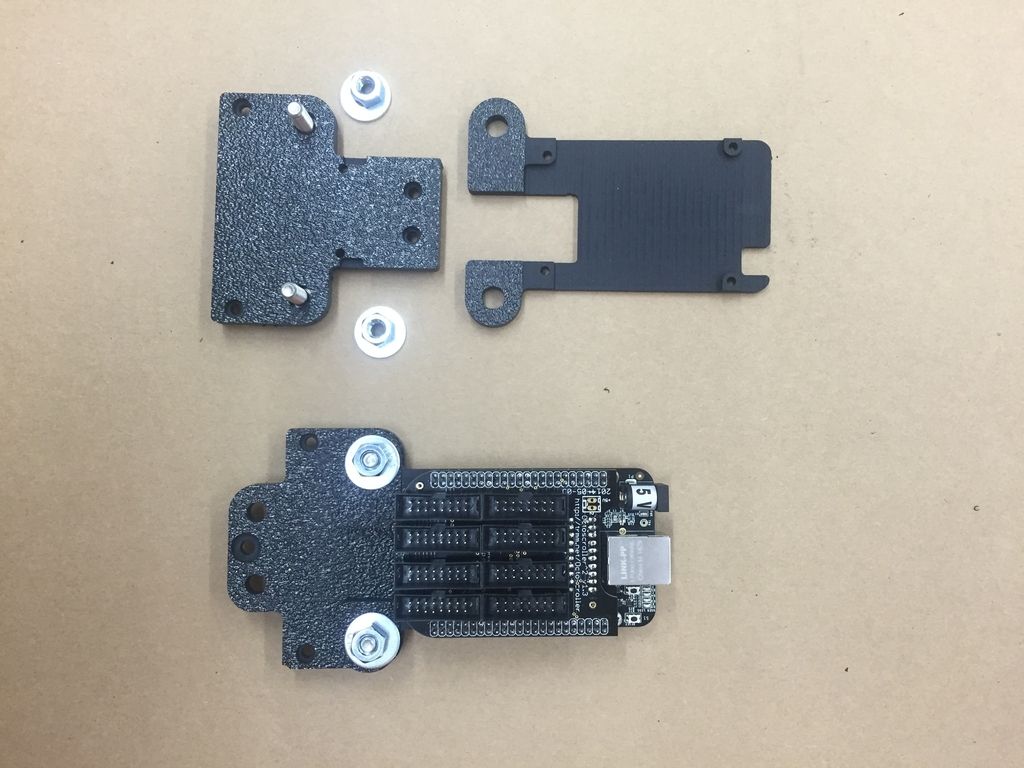

I also finished the smaller BBB mount that fits off to the side. By using this plate, you can use the factory 4" long ribbon cables to reach the first two rows of panels. This is perfect when you plan on doing a scrolling text matrix that is only 2 P10's tall! The BBB mounting plate can be bolts to any of the T's with or without the side mounting tabs. This plate can be installed on any of the T's or X's so the BBB can really be mounted anywhere on the backside of the matrix.

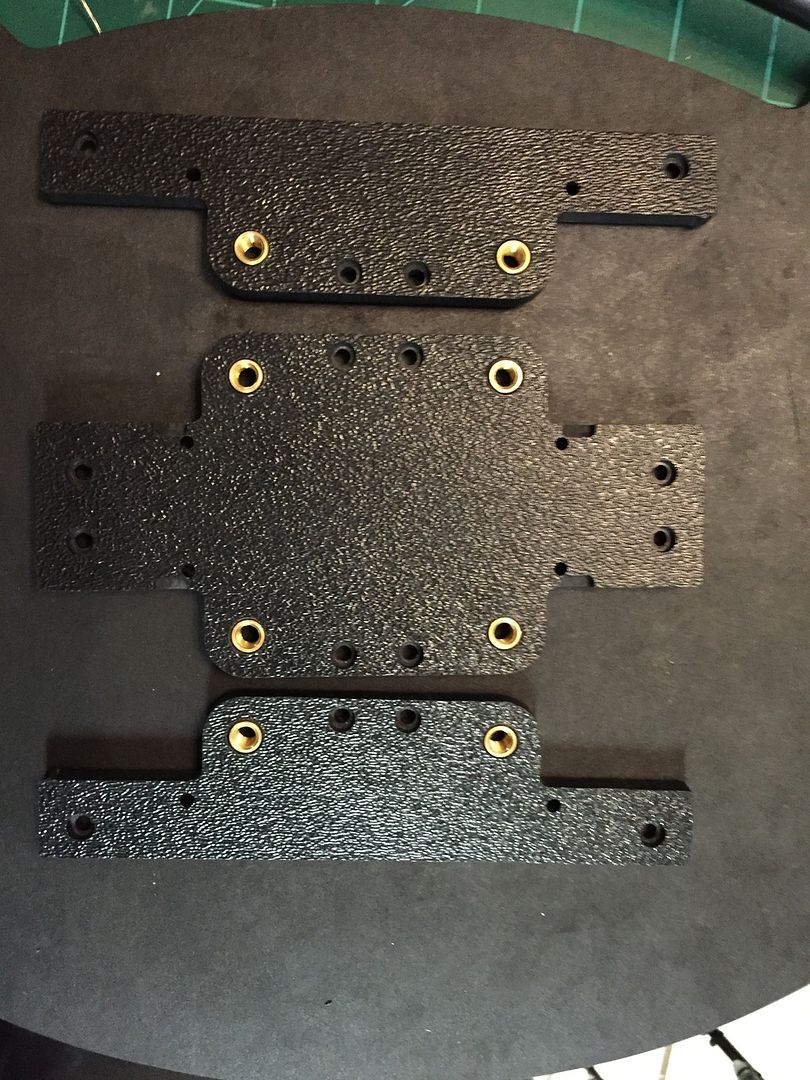

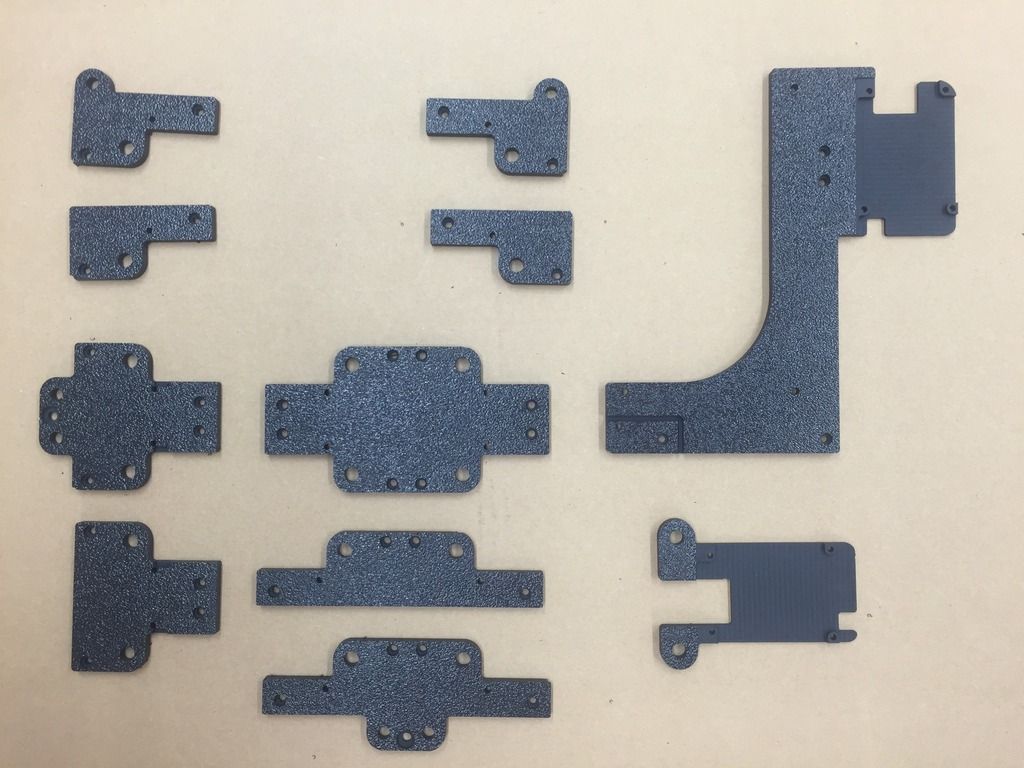

I made all of the T's for the sides or top and bottom to come with or without the revised side mounting tabs so you can install the finished Matrix Panel in either orientation. It also works with our soon to be released P10 Enclosure.

The rest of the collection:

I forgot to add the pic of the additional Power Supply mount. I cut off the BBB plate so if you use the new BBB mount listed above you can clean up the install.

Thanks,

James

I also finished the smaller BBB mount that fits off to the side. By using this plate, you can use the factory 4" long ribbon cables to reach the first two rows of panels. This is perfect when you plan on doing a scrolling text matrix that is only 2 P10's tall! The BBB mounting plate can be bolts to any of the T's with or without the side mounting tabs. This plate can be installed on any of the T's or X's so the BBB can really be mounted anywhere on the backside of the matrix.

I made all of the T's for the sides or top and bottom to come with or without the revised side mounting tabs so you can install the finished Matrix Panel in either orientation. It also works with our soon to be released P10 Enclosure.

The rest of the collection:

I forgot to add the pic of the additional Power Supply mount. I cut off the BBB plate so if you use the new BBB mount listed above you can clean up the install.

Thanks,

James

Last edited: